Lifting a truck 6+ inches with a combination of a suspension lift and a body lift is the easiest way to clear 35”+ tires. However, in the process you lose stability both on and off road. This can lead to more likely roll overs on the trail as well as poor on-road manners. Not to mention the fact that a tall suspension lift does not always mean a flexy suspension lift. And a flexy suspension is one that will keep your tires in contact with the trail and maintain your forward progress. So, how do you achieve the goldilocks setup of large tires AND low ride height. The answer is the firewall tub. The firewall is the wall that separates the engine compartment from the passenger compartment. Coincidentally, this also happens to be the greatest source of rubbing and tire interference when fitting larger tires. A firewall tub involves cutting back the offending firewall sections and replacing them with new sheet metal that will provide the space required for those big meats to work their magic on the trail. This article is meant to serve as a resource for those looking to take the plunge and tub their own vehicle. I will cover just about every detail required to clear 35” tires on a 3rd generation Toyota 4Runner AT ANY RIDE HEIGHT. Yes, you read that right. Any. Ride. Height. (I will explain more later). Some of these details will include setting your rear bumpstop height, relocating your vacuum canister and windshield washer reservoir, and how much fender trimming is required. While these details are specific to the 3rd generation 4Runner (and 1st generation Tacoma), the general procedure covered in this article is applicable to any vehicle you choose to tub.Disclaimer: This article is simply an informational resource to give you an idea of what is required to tub a vehicle for over sized tires before deciding to attempt it yourself. Coastal Offroad nor myself are responsible for any problems you encounter while tubbing or as a result of tubbing your own vehicle.

What You’ll need:

- Floor Jack

- Jack Stands

- Wrench and socket set

- Welder

- 16 gauge sheet metal (~4 square feet to be safe)

- 4-5” angle grinder

- Smaller die grinder

- Cutting disks

- Flap disks

- Masking tape

- Sharpie marker

- Polyurethane sealant

- Primer

- Rubberized undercoating or bedliner

- Automotive edge trim

- Extra adhesive (for edge trim)

- Touch up paint

Understanding IFS

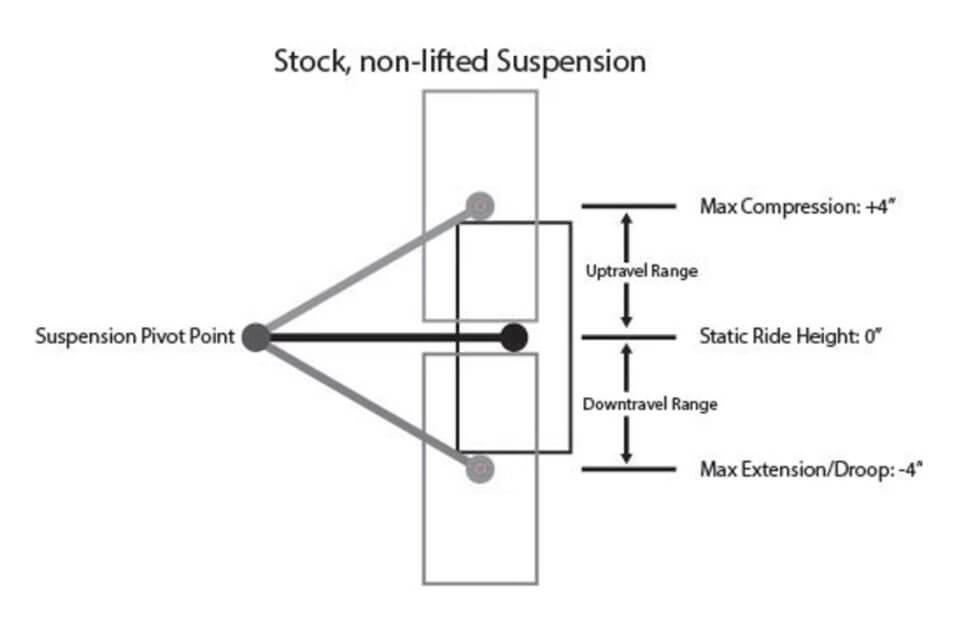

In this section, I am going to ramble on about the mechanics and nuances of independent front suspension to give you a better understanding of why I perform the fender tub the way I do. First off, let’s get one thing straight. IFS suspension lifts do not help you clear bigger tires. They also do not increase wheel travel, short of a full-on long travel suspension setup that uses longer lower control arms. Yes, you may gain a small amount of extra droop or down travel by forcing longer strut assemblies into your front end and going to Uniball upper control arms, but that’s it. The only thing that an IFS lift does is change the static ride height of your front suspension. Static ride height is the height that your vehicle sits at while on level ground with only the weight of the vehicle compressing it. So what does this mean? Let’s look at the following example:Any given suspension needs up and down travel to function properly. This allows your tires to move up and out of the way when they hit a bump, or drop down into dips and potholes. A stock 3rd generation 4runner has approximately 8” of wheel travel from max extension/droop to full bottom out on the bumpstops. When at static ride height, let’s say it sits right in the middle of its 8” of suspension travel, giving it 4” of up travel and 4” of down travel as shown below. The wheel positions at max compression and extension are shown in grey and the wheel position at static ride height is shown in black.

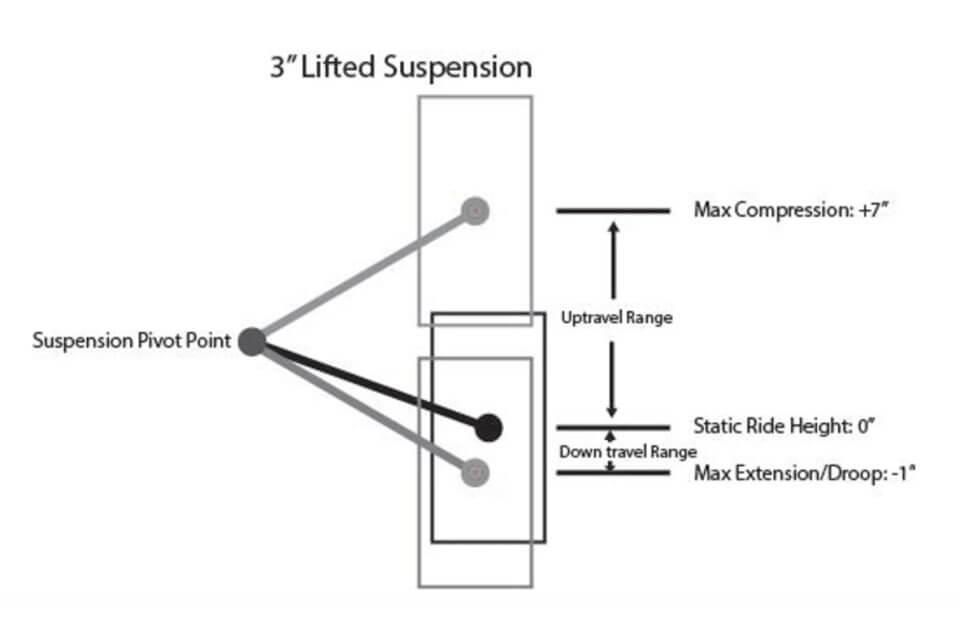

This travel range give the tires a comfortable suspension range to follow both bumps and dips in the terrain. Then, a 3” suspension lift is installed, moving the static ride height position 3” downwards in its 8” of total suspension range, as shown below:

Starting the Clearance Process

Now that I’ve given a bit of background on how IFS works and what our end goal is - Zero tire rub at full compression, lock to lock steering – let’s dive into it.The first step is to jack up the front end of your vehicle and support it on jack stands. Remove both front tires so you have space to work and then remove the front fender liners, front bumper (if you still have a stock front bumper), and the fenders themselves. The front fender liners will not be reused. The fenders themselves are removed to give you space to work and so they can be trimmed.With those pieces removed, it’s time to remove the windshield washer system from the front of the passenger side wheel well. The washer reservoir must be replaced with a smaller unit and moved up into the engine bay. I don’t cover this relocation in this article, but there are other resources out there as well as complete relocation kits that can be purchased. Below is a picture of the wheel well space created by relocating the washer reservoir.

It is also necessary to relocate the vacuum system canister located at the front of the driver side wheel well. Luckily, I found that it could be simply moved further into the corner of the wheel well without any tire interference or the need to extend the vacuum line. I simply unbolted the bracket, bent the bracket arms slightly, and push the canister as far into the top corner of this space as possible. I then reinstalled the canister using an existing hole in the wheel well and an additional nut and bolt. Easy!

Once you have a good idea, remove the tire and start cutting! I used a combination of a 5” angle grinder with cutting wheels and a smaller pneumatic grinder with a 3” cutting wheel on it. Every so often, reinstall the tire, jack it up and turn the steering lock to lock again to reassess where more material needs to be removed. While cutting, be extra careful that none of the electrical wires or components have shifted and have fallen back down into harm’s way. I can assure you that I will not be writing a how-to article on how to re-wire your 4runner so you’re on your own for that one. Below is the final amount of cutting required for the driver's side:

Creating the Firewall Tub

Once your tires can turn lock to lock steering at full compression without rubbing anything in the wheel well, its time to patch up the gaping hole you’ve made in your firewall. This process can be quite time consuming, as you most likely have a very irregularly shaped hole to fill with flat sheet metal. However, with some patience I am confident that anyone can do this step and end up with a decent end result. I used 16 gauge sheet steel as it’s a nice compromise between strength and malleability. Depending on how experienced you are with working with sheet metal, decide ahead of time if you are going to cover the entire hole with one piece of sheet metal, or piece it together with several smaller pieces. One large piece will leave you with a cleaner finished product but will be much more difficult to contour to the opening. Start by laying a piece of cardboard (something similar in thickness to a cereal box is ideal) over the opening, contouring the cardboard into the hole as you would the sheet metal to achieve the max possible amount of tire clearance. You want to make sure you aren’t losing the tire clearance you just worked so hard to gain by using a poorly contoured sheet metal tub. Trace the shape of the opening onto the backside of the cardboard. Once you have a rough outline, cut out the traced shape of cardboard and transfer that onto your sheet metal. Cut out the sheet metal, erring on the side of caution by cutting the piece slightly bigger than required. It’s much better to have the piece slightly too large and fold its edge over your firewall opening rather than ending up with gaps. Unlike with thicker steel plate, you will burn through the thin factory firewall sheet metal unless you have a generous overlap between the firewall and your sheet metal patch. Once you are happy with your metal patch, prepare your firewall for welding by taking a flap disk and sanding off the undercoating surrounding the opening. A ½”-3/4” strip all the way around should be sufficient. Be careful to sand it just enough to expose the bare metal and no more. You are already working with very thin steel, and excessive sanding will make it even thinner and thus easier to burn through with your welder!Before tacking your piece of sheet metal in place, double check that your damp towel is still in place behind your firewall to catch any sparks or excessive heat from damaging your interior. Now, take your sheet metal patch and lay it over the opening. To achieve a nice contour that maximizes tire clearance, I started by tacking the top edge to the firewall and then hammering the sheet metal into the opening. I then repeated this process of tacking and then hammering until the whole piece of sheet was contoured and tacked to the firewall. If you are using multiple pieces of sheet metal, repeat this process until the whole opening is filled. The driver's side looked like this:

Then, finish off all sheet metal edges with weld beads. Take your time and use many short passes with the welder. Depending on your welder and amount of sheet metal welding experience, you may only be able to weld for a couple seconds at a time before burning through the firewall. So be patient and take your time. Once fully welded, move to the other wheel well and repeat this process. After tubbing, my passenger side looked like this:

I followed this up with a few coats of primer and then a rubberized undercoating that will absorb road debris spray rather than chipping off. Below are some views of the finished driver side tub:

And the passenger side:

Trimming your Outer Fenders

It’s now time to trim your outer fenders. There are a number of different ways to do this. Some choose to cut the absolute minimum amount of fender and essentially contour the fender to the shape of the tire at full compression by trimming the fender only where the tire will contact it. I personally don’t like this method as you end up with a fender profile that has been obviously cut. Instead, I measured how much tire to fender interference there was at the top of the tire (the point of greatest interference) and then removed an even amount of material from the whole fender profile. This will maintain the factory wheel well profile and result in a much cleaner end result. The one exception to this is the area at the bottom of the fender near the firewall. When the wheels are turned, this area will experience a lot of interference so requires more trimming. In the end, I ended up taking off 1.25” from the whole fender profile, but then tapered this cut to 2” for the bottom 12-16” of the fender near the firewall.How did I measure out a clean cut? I simply plotted points all around the fender opening by measuring 1.25” from the fender edge and marking the point with a permanent marker. I marked a point every couple inches around the fender and then connected the points with a straight edge, as shown above.

Once both fenders are cut to their final profile, be sure to paint the exposed metal edge to prevent corrosion. I then finished the edge with some black automotive edge trimming. The adhesive on the product I purchased wasn’t the best, so I added some super glue to the fender lip and pressed the edge trimming firmly in place. This creates a clean, factory looking fender edge and also protects the edge from rock chips and the resulting corrosion. I will go as far as to say that I think my cut fender profile looks better than the original factory lines!

You are now pretty much finished clearancing your 4Runner for 35’s! Reinstall your fenders, front struts/coil overs, and wheels, being sure to tighten everything to their specified torque values.

Move to the interior and put all of the wiring you have displaced back into position. Replace the carpet in its correct spot. Depending on the shape of your tub profile, your interior kick panels may or may not require trimming to fit properly. For me, I was able to reinstall my passenger side kick panel cut-free, but my drivers side panel did require some trimming to get back in place. Even still, my dead pedal is about half the size that it used to be but like anything, you will get used to it. At the end of the day, it’s a small price to pay for fully functional 35’s! Here is a view of my passenger side foot well:

Here are some photos of the finished fender and firewall profiles with the tires reinstalled. As you can see, my cut line smoothly follows the factory fender line until the bottom corner, where it tapers to a slightly more substantial cut. The drivers side:

And the passenger side:

And the whole truck, sitting nice and low on those 35's.

I hope this article was informative to you and will give you the confidence to tackle this modification on your own vehicle. While it is a very time-consuming project that has many irreversible aspects to it, I am confident that anyone with a small amount of mechanical inclination is capable of doing it. Just plan everything out in advance and take your time. I promise you that the end result of 35’s and a low ride height is worth it!